From Plant to Product

From Bamboo Tube to Bamboo Strip

We carefully select MosoTW bamboo that is over five years old. After harvesting, the mature bamboo tubes are split lengthwise, and the outer bamboo skin is removed.

Untreated bamboo strips retain a natural light-yellow hue but can be processed further for different finishes.

Steaming imparts a subtle brown tone (carbonized), while pyrolysis results in a deep chocolate-brown color.

From Bamboo Strip to Flooring

After processing and drying, bamboo strips can be crafted into final products using various methods.

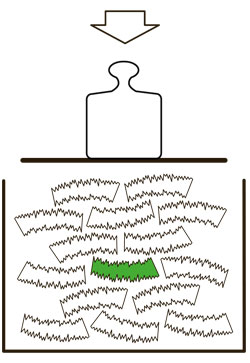

Horizontal Pressing

By laying bamboo strips flat and bonding them together with adhesive, a horizontally pressed product is created,

showcasing the distinctive bamboo grain and nodes on the surface.

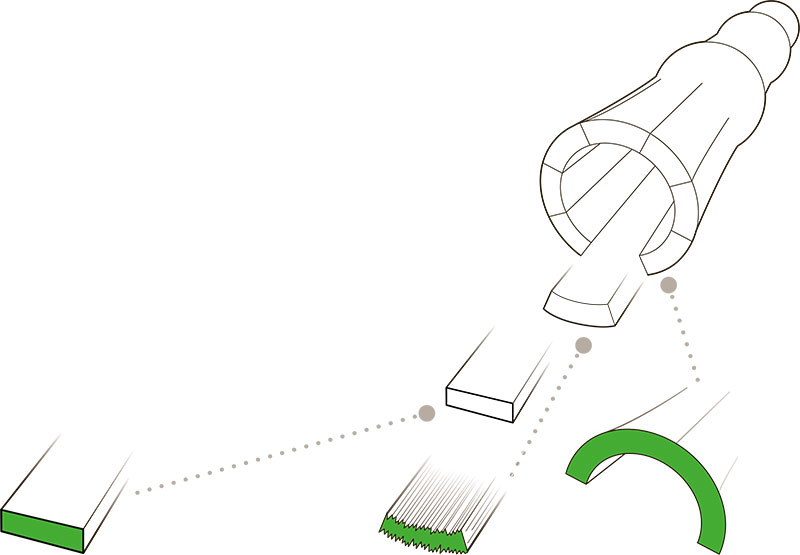

Surface Veneer

The bamboo strips are connected to a soft latex backing.

The latex backing provides exceptional walking comfort while also offering excellent sound absorption properties.

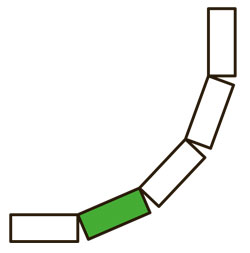

Vertical Pressing

By positioning bamboo strips vertically and bonding them together with adhesive, a vertically pressed board is created,

showcasing subtle bamboo nodes on its surface.

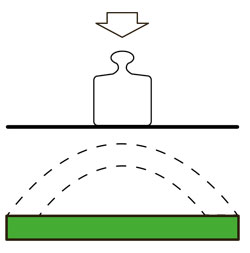

High-Density Bamboo

Bamboo strips are compressed under high pressure, and adhesive is cured at high temperatures to bond the strips together.

The surface texture appears classic and varied, while the resulting material is even harder than the finest hardwoods.

Bamboo tubes are unfolded through a specialized process to create a solid bamboo surface layer.

This technique results in flooring that is exceptionally durable and hard.